Fitness Equipment Manufacturer In China

Direct From Factory – No Middleman Markups! !

- Factory Direct Price

- OEM & ODM Support

- Fast Prototyping & On-time Delivery

Fitness Equipment Manufacturer In China

Direct From Factory – No Middleman Markups! !

- Factory Direct Price

- OEM & ODM Support

- Fast Prototyping & On-time Delivery

With over 15 years of experience in fitness equipment design and manufacturing, WCAGO offers high-precision CNC machining and robust fabrication facilities.

Our advanced production lines include CNC tube bending machines, laser cutting, robotic welding, and automatic powder coating — supporting your brand with full OEM/ODM services.

From design consultation to production and after-sales, our expert engineers provide end-to-end support to ensure every order is executed perfectly.

Wide Range of Commercial-Grade Equipment Options

Discover WCAGO’s comprehensive line of commercial fitness equipment, engineered to meet the demands of professional gyms, sports centers, and training studios worldwide. From Smith Machines and Power Racks to Spin Bikes and Ellipticals, every unit is designed for durability, safety, and smooth performance.

Our Core Product Categories

Explore WCAGO’s flagship product ranges — each designed for professional use, precision-built for stability, and customizable for your brand’s needs.

Precision-Guided Strength Training for Every Athlete

- Linear bearing glide system

- Counterbalance options available

- Compatible with benches and cable systems

Versatile Support for Multi-Angle Workouts

- Flat, incline, decline benches

- 1000+ lbs tested load capacity

- PU leather with anti-slip texture

Engineered for Lower-Body Power and Precision

- Dual-function machines available

- Integrated weight stacks

- Clear instruction placards

Versatile training frames designed for heavy lifting, functional workouts, and personal training spaces.

- Adjustable resistance and seat positioning

- Silent belt drive system for smooth riding

- Compact and durable design for intensive use

High-Intensity Cardio with Industrial Durability

- Heavy-duty steel frame construction

- Smooth belt-driven system

- Adjustable resistance for all fitness levels

Smooth, Low-Impact Training for All Fitness Levels

- Fluid stride with adjustable angles

- Ergonomic alignment for natural movement

- Heavy-duty commercial-grade steel frame

Fully Customizable Fitness Equipment Solutions

Co-Develop Your Next-Gen Fitness Products — From Engineering to Mass Production

- End-to-End OEM/ODM Service –From Sketch to Shelf: We Support Your Product Launch Every Step of the Way

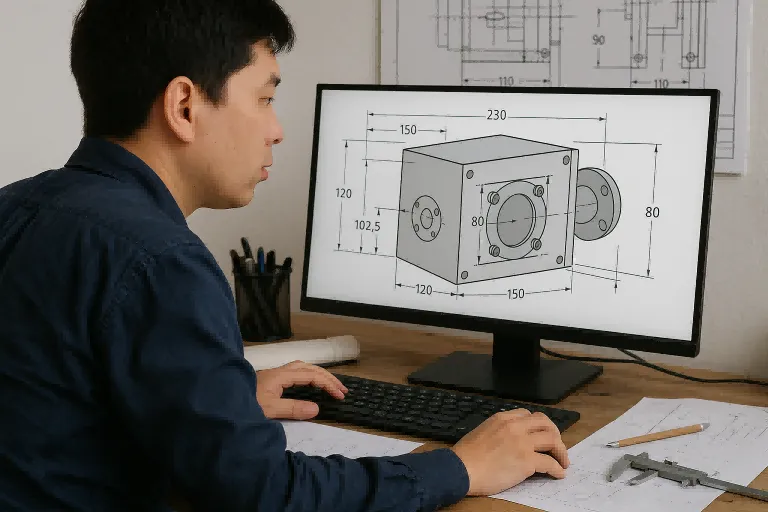

- In-house Engineering & R&D Support – Rapid prototyping, 3D modeling, and mechanical validation

- Premium Frame Materials – Q235/Q345 steel with industrial-grade powder coating or electroplating

- Brand Customization – Logo engraving, color matching, packaging & documentation ready for market

- Size & Structure Customization – Tailored to your market specs and user ergonomics

- Flexible MOQs & Scalable Production – From initial samples to container-level orders

- Color Options – Over 100+ standard & custom finishes for cohesive brand identity

- Sample Approval Before Mass Production

Why Leading Buyers Choose WCAGO

Reliable Supply

25,000㎡ smart factory equipped with CNC tube bending, robotic welding, laser cutting, and automatic powder coating — ensures stable, high-volume production for growing demand.

Custom Branding

Full-spectrum OEM/ODM services including frame/logo/color customization, packaging design, and documentation — tailored for private label brands.

Global Compliance

Certified with CE, ISO9001, SGS, and experienced in export documentation, packaging regulations, and customs processes for 60+ markets.

Cost Efficiency

Factory-direct pricing without middlemen or trading commissions. Lower sourcing costs mean higher margins for your business.

Fast & Flexible Delivery

25–40 day lead time, low MOQs, and support for mixed container loading — ideal for startups and large-volume distributors alike.

Technical & Engineering Support

Dedicated engineers offering 3D design, mechanical validation, and after-sales service — ensuring a seamless product launch and long-term maintenance support.

Production Zones

WCAGO’s factory is divided into specialized zones, each equipped with advanced machinery and operated under strict quality protocols. From raw materials to finished products — every process is optimized for precision, consistency, and performance.

Raw Material Zone

We source and inspect high-quality steel to ensure a strong foundation for every machine.

Tube Bending Zone

Steel pipes are bent with CNC precision to form durable and ergonomic frame structures.

Tooling Storage Zone

We store and maintain production tools to ensure efficient and accurate manufacturing at every stage.

Powder Coating Zone

Frames receive rust-proof, uniform finishes through controlled powder coating.

Tube Cutting Zone

Pipes are precisely cut to length, forming the base for structural accuracy.

Stamping Zone

Steel plates are stamped into reinforced components with hydraulic force.

Welding Zone

Robotic and manual welding ensue strong, consistent joints on all equipment

Finished Product Zone

Each machine is fully assembled, tested, and prepared for global delivery.

About WCAGO

WCAGO is a professional fitness equipment manufacturer in China, with a 25,000㎡ production base equipped with automated production lines, rigorous quality control, and in-house R&D and engineering teams.

With years of industry expertise and international trade show participation, we deeply understand the needs of global brands, importers, wholesalers, and distributors across various market segments — from retail to commercial gyms.

We offer not only standardized product lines, but also fully customized training solutions tailored to your brand and local market demands.

Our Trade Show Presence

We actively participate in major international fitness and sporting goods exhibitions, allowing us to stay ahead of industry trends and better understand the needs of brands, distributors, and gym operators worldwide.

Through face-to-face communication with clients at events like FIBO, IHRSA, and China Sport Show, we’ve built long-term partnerships and delivered customized solutions that match each market’s specific demands.

Choosing WCAGO means working with a manufacturer that knows your market — because we’ve been there.

Our Production Advantage

We are a factory-direct supplier, eliminating unnecessary middlemen and maximizing your profit margin. Whether you’re a retailer, wholesaler, or chain operator, partnering with WCAGO means gaining a responsive team that supports you from design to delivery.

Frequently Asked Questions

Project Support

We support global partners with one-stop solutions for gym equipment sourcing — including OEM/ODM services, engineering support, and bulk delivery capabilities. Whether you’re building a chain gym, developing a brand line, or supplying a government project, WCAGO is your reliable manufacturing partner.

Yes. We offer full OEM & ODM services, from structural design and color customization to private label branding. Our R&D and engineering teams can support you throughout the product development cycle.

Our factory covers 25,000㎡ with automated production lines. We handle small-batch prototyping to full-container orders, typically delivering within 25–40 days, depending on order volume and customization requirements.

Absolutely. All materials and components are tested to meet ISO standards, and we support CE, RoHS, TUV, and other certification needs for specific markets.

We implement strict quality management systems across all stages — from raw material inspection and welding accuracy checks, to full machine testing and final QC before packaging.

Yes. We welcome on-site visits and offer video factory tours, live inspections, and sample machine testing — especially helpful before container shipment.

We offer after-sales technical support, spare parts supply, and long-term cooperation plans. For repeat orders, we maintain tooling, color codes, and product records to ensure consistency.

Yes. We provide flexible loading solutions, including mixed equipment loading, space-efficient packaging design, and container optimization plans to reduce shipping costs and avoid damage during transit.

Looking for a Source Manufacturer to Boost Your Margins?

Work directly with a fitness equipment factory that offers custom frame sizes, color schemes, materials, and branding options. With extensive manufacturing experience and deep insight into global market demands, WCAGO helps you cut costs, shorten lead times, and bring more value to your business.

Get Your Custom Equipment Design Plan

Tell us your product needs, layout requirements, or brand vision — our engineering team will provide a professional design solution tailored to your market and audience.